Mit-ivy sanoati metallari mukammal penetratsion quvvatga ega bo'lgan rivojlangan akril lateksli muhrlangan astar

Ilova

U po'lat substratlarga va shu kabi suvga asoslangan primerlarga mukammal yopishadi va bo'yoq to'lqini quriganidan keyin mukammal fizik-mexanik xususiyatlarga ega.

5. Bo'yoq plyonkasi quritgandan keyin yorug'likni mukammal darajada saqlaydi va rangni saqlaydi.

Tavsiya etiladigan qo'llanma Bu yuqori himoya talab qilinadigan yuk mashinalari, mashinalar qismlari, engil sanoat uskunalari va boshqalarni drenajdan himoya qilish uchun javob beradi.

Texnik ma'lumotlar rang-barang

Yuzaki quruq (50% aralashish) 15 ℃ C <1 soat ; 25'C <0,5 soat

Qattiq quruq (50% namlik) 15'C <48 soat; 25 ° C <24 soat

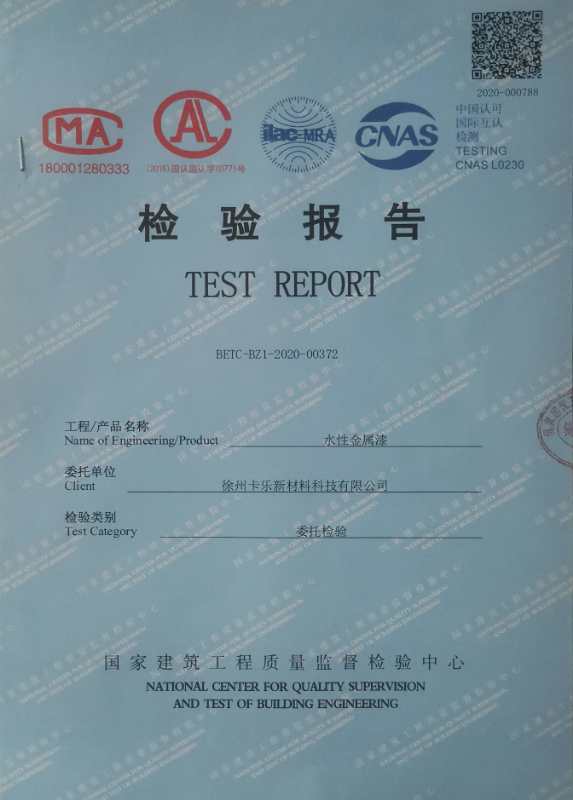

Xitlar "kg.cm" 50

Suv (50 ± 5mm) 72 soatlik bo'yoq plyonkasi pufakchani hosil qilmaydi, yiqilishga yordam bermaydi va zanglamaydi.

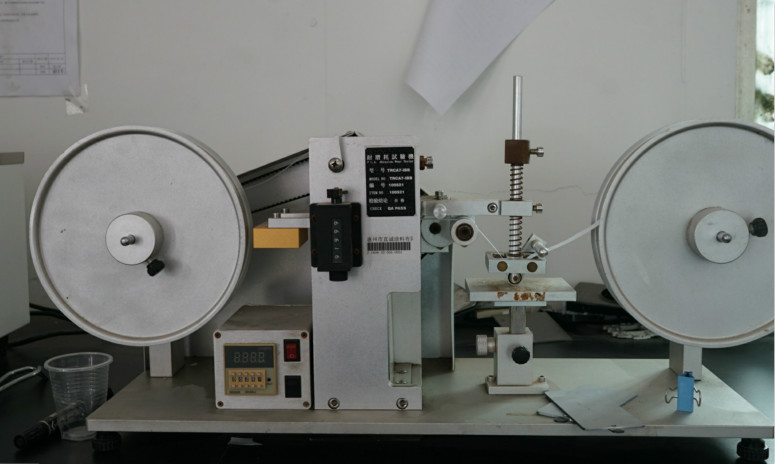

Qattiqligi 0,3 (ikki mayatnik) mexanik xususiyatlarni sinash plyonkasining qalinligi (23 ± 3jkm)

Yopishtirish (Hegelian) 1-daraja

Yuzaki ishlov berish Qoplangan materialning yuzasida namlik, yog ', kislotali uglerod va kul bo'lmasligi kerak.

Tez ma'lumotlar

Teri oksidi bo'lgan po'lat: Sa2.5 darajasiga qadar ishlov berish kabi otish yoki qumni portlatish usullari, bu erda qumni portlatish mumkin emas, mexanik silliqlash yoki

Barcha suzuvchi singan yelkalarni olib tashlash uchun kimyoviy davolanish.

Oksidli terisiz po'lat: Sa2.5 gacha qum bilan ishlangan (otilgan) va St3 ga qadar havo bilan ishlaydigan, silliqlash asboblari.

Kuygan kamar joylarini payvandlash, olovni kesish yoki fişekni tuzatish: St3 darajasiga qadar silliqlash.

Qadimgi bo'yoq plyonkali tayanch material: bo'shashgan eski bo'yoq zarralarini va zangni tozalang va St3 ga qumni havo yoki elektr zımpara asboblari bilan olib boring.

Odatiy bo'yash to'plami H902 suvga asoslangan astar bilan ishlatilishi mumkin, yoki umumiy dekorativ po'stin sifatida yakka o'zi ishlatilishi yoki boshqa turdagi astar mahsulotlari bilan ishlatilishi mumkin (tekshirish uchun moslashtirish kerak).

Construction data Table dry (50% temperature) 15'C<th;25℃C<05h Actual dry (50% humidity) 15℃C<24h;25℃<12h Density about 1.1-1.20g/cm' Theoretical coating rate 0.15-0.2kg/m' (dry film 40-50) μm)

It is recommended to apply 2 coatings, which can be applied in the way of warm touching temperature to ensure that the dry film is 40-50μm.

To be sanded and finished with sandpaper.

Construction method Air or robot spraying is possible. Mix the paint before use, adjust the viscosity according to the construction method.

Add 5-15% of water. Add water and stir evenly, then leave the surface to work without bubbles.

Construction environment 1. The brain playground should have good ventilation and dust removal facilities to ensure the quality of construction.

2. The construction should be carried out under the condition that the mixing degree is above 5℃C and the relative humidity of the environment should be <70%.

3. The substrate temperature shall be not less than 5' and shall be more than 3'C above the air dew point temperature.

washout

| Vehicle Type | 100% Acrylic Latex | |

| COMPOSITION (nominal) | Pigment : Lightfast Non-Lead Pigments & Mineral Extenders.

Blinder : Acrylic Emulsion. Solvent : Water. |

|

| Volume Solids | 31.8% | |

| Coverage per Gallon at Recommended Film Thickness | 400 –450 Sq. Ft. (37-42 m2) | |

| Recommended Film Thickness

(Depending on surface texture and porosity. Be sure to estimate the right amount of paint for the job. This will ensure color uniformity and minimize the disposal of excess paint) |

Dry 1.2 mils

Wet 3.8 mils |

|

| Dry Time @ 77° F (25° C) @ 50% RH

(High humidity and cool temperatures will result in longer dry, recoat and service times.) |

To Touch 1 Hour

To Recoat 2 to 4 Hours |

|

| Dries By | Evaporation, Coalescence | |

| Viscosity | 99 ± 2 KU | |

| Gloss / Sheen | Flat (5-10 @ 85°) |

| Shipping time by Sea (Just for reference) | ||||||||

|

North America |

11~30 days | North Africa | 20~40 days | Europe | 22~45 days | South-east Asia | 7~10 days | |

| South America | 25~35 days | WestAfrica | 30~60 days | MiddleEast | 15~30 days | East Asia | 2~3 days | |

| Middle America | 20~35 days | EestAfrica | 23~30 days | Ocenia | 15~20 days | South Asia | 10~25 days | |

FAQ

1.About Sample

We provide free sample for testing.

2.OEM,ODM service available.

3.According to customer's request, packed with pallet or without pallet.

Tile adhesive(20kg/bag)packing with pallet specification:

64 bags/pallet = 1.28 MT/pallet

72 bags/pallet = 1.44 MT/pallet

One full 20ft container max loading 27.6MT.

With pallets can load 1360 bags, without pallet can load 1380 bags.